Introduction to CNC Machines for Wood

CNC machines, or Computer Numerical Control machines, have revolutionized the woodworking industry by automating complex cutting, carving, and shaping tasks. These machines use computer-controlled tools to create precise and intricate designs in wood, significantly improving efficiency, accuracy, and repeatability. A CNC machine for wood is a specialized type of CNC equipment designed specifically for woodworking applications. It is widely used in industries such as furniture manufacturing, cabinetry, sign-making, and custom woodworking projects.

In this article, we will explore what a CNC machine for wood is, how it works, its components, types, applications, benefits, limitations, and key considerations when choosing one. By the end, you will have a comprehensive understanding of CNC machines for wood and their role in modern woodworking.

How Does a CNC Machine for Wood Work?

CNC machines for wood operate by following pre-programmed instructions to manipulate cutting tools and other machinery components. These instructions are typically created using CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. The process involves several key steps:

1. Designing the Project

The first step in using a CNC machine for wood is designing the project using CAD software. This software allows the user to create detailed 2D or 3D models of the desired object. The design includes all dimensions, shapes, and features of the final product.

2. Generating Toolpaths

Once the design is complete, CAM software is used to generate toolpaths. Toolpaths are the precise movements that the cutting tool will follow to create the design. The software also determines cutting parameters such as feed rate, spindle speed, and depth of cut.

3. Loading the Program

The toolpath data is then converted into G-code, a programming language that CNC machines understand. The G-code is loaded into the CNC machine’s controller, which interprets the instructions and executes the cutting process.

4. Setting Up the Machine

Before starting the machining process, the operator sets up the CNC machine. This involves securing the wood material on the machine’s worktable, selecting the appropriate cutting tools, and calibrating the machine to ensure accuracy.

5. Machining the Wood

Once everything is set up, the CNC machine begins the machining process. The cutting tool moves along the programmed toolpaths, removing material from the wood to create the desired shape and design. The process is highly precise and can produce intricate details that would be difficult or impossible to achieve manually.

6. Finishing the Product

After the machining process is complete, the finished product may require additional finishing steps such as sanding, painting, or assembly. However, CNC machines often produce parts with smooth surfaces and precise dimensions, reducing the need for extensive post-processing.

Components of a CNC Machine for Wood

CNC machines for wood consist of several key components that work together to perform machining tasks. Understanding these components is essential for operating and maintaining the machine effectively. Here are the main components:

1. CNC Controller

The CNC controller is the brain of the machine. It interprets the G-code instructions and sends commands to the machine’s motors and other components. The controller ensures that the cutting tool moves accurately along the programmed toolpaths.

2. Cutting Tool

The cutting tool is the part of the machine that comes into contact with the wood material. It removes material to create the desired shape and design. Common cutting tools used in woodworking CNC machines include end mills, router bits, and engraving tools.

3. Spindle

The spindle is a motorized component that holds and rotates the cutting tool. It provides the necessary speed and torque for cutting through wood. Spindles are available in various power ratings, depending on the machine’s intended use.

4. Worktable

The worktable is the surface on which the wood material is secured during machining. Some CNC machines have vacuum tables that use suction to hold the material in place, while others use clamps or fixtures.

5. Linear Motion System

The linear motion system consists of rails, bearings, and motors that enable the cutting tool to move along the X, Y, and Z axes. This system ensures precise and smooth movement during machining.

6. Frame

The frame provides structural support for the CNC machine. It is typically made of steel or aluminum to ensure stability and durability during operation.

7. Software

Software is an integral part of a CNC machine for wood. CAD software is used for designing the project, while CAM software generates the toolpaths. The machine’s controller software interprets the G-code and controls the machining process.

Types of CNC Machines for Wood

CNC machines for wood come in various types, each designed for specific applications and levels of complexity. Here are the most common types:

1. CNC Routers

CNC routers are the most common type of CNC machine used in woodworking. They are versatile and can perform tasks such as cutting, carving, engraving, and drilling. CNC routers are ideal for creating furniture, cabinetry, signs, and decorative items.

2. CNC Laser Cutters

CNC laser cutters use a high-powered laser beam to cut or engrave wood. They are known for their precision and ability to create intricate designs. Laser cutters are commonly used for making signs, art pieces, and detailed engravings.

3. CNC Plasma Cutters

Although more commonly used for metal, CNC plasma cutters can also be adapted for woodworking. They use a plasma torch to cut through materials. However, they are less common in woodworking compared to routers and laser cutters.

4. CNC Lathes

CNC lathes are used for turning operations, where the wood material rotates while the cutting tool removes material. They are ideal for creating cylindrical objects such as table legs, spindles, and bowls.

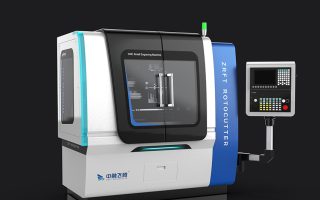

5. CNC Milling Machines

CNC milling machines are similar to CNC routers but are designed for more heavy-duty tasks. They can handle thicker and harder wood materials, making them suitable for industrial applications.

Applications of CNC Machines for Wood

CNC machines for wood are used in a wide range of applications, from small-scale projects to large industrial production. Here are some common applications:

1. Furniture Manufacturing

CNC machines are widely used in the furniture industry to create chairs, tables, cabinets, and other pieces. They enable manufacturers to produce high-quality furniture with intricate designs and precise dimensions.

2. Cabinetry

CNC machines are ideal for making custom cabinets with detailed carvings and precise joinery. They allow for efficient production of cabinet components, including doors, panels, and frames.

3. Sign-Making

CNC routers and laser cutters are commonly used for creating wooden signs with intricate lettering and designs. They are also used for engraving logos and artwork on wood.

4. Decorative Items

CNC machines are used to create decorative items such as wall art, sculptures, and ornaments. They enable artists and craftsmen to produce detailed and unique designs.

5. Prototyping

CNC machines are valuable tools for prototyping new products. They allow designers to quickly create and test wooden prototypes before moving to mass production.

Benefits of CNC Machines for Wood

CNC machines offer numerous advantages over traditional woodworking methods. Here are some of the key benefits:

1. Precision and Accuracy

CNC machines can produce highly precise and accurate cuts, ensuring consistent quality in every piece. This level of precision is difficult to achieve with manual tools.

2. Efficiency

CNC machines can complete complex tasks quickly and efficiently, reducing production time and labor costs. They can also operate continuously, increasing productivity.

3. Versatility

CNC machines can perform a wide range of tasks, from cutting and carving to engraving and drilling. This versatility makes them suitable for various woodworking applications.

4. Repeatability

Once a design is programmed into the machine, it can produce identical copies of the same product with consistent quality. This is especially useful for mass production.

5. Reduced Waste

CNC machines optimize material usage by minimizing waste. They can cut parts with minimal scrap, reducing material costs and environmental impact.

Limitations of CNC Machines for Wood

While CNC machines offer many benefits, they also have some limitations:

1. High Initial Cost

CNC machines can be expensive to purchase and set up, making them a significant investment for small businesses or hobbyists.

2. Learning Curve

Operating a CNC machine requires knowledge of CAD/CAM software and machine programming. Beginners may need training to use the machine effectively.

3. Maintenance

CNC machines require regular maintenance to ensure optimal performance. This includes cleaning, lubrication, and replacing worn parts.

4. Limited Material Thickness

Some CNC machines have limitations on the thickness of wood they can handle. For thicker materials, specialized machines may be required.

Key Considerations When Choosing a CNC Machine for Wood

When selecting a CNC machine for woodworking, consider the following factors:

1. Size and Work Area

Choose a machine with a work area that suits your project needs. Larger machines can handle bigger pieces of wood but may require more space.

2. Power and Speed

Consider the spindle power and cutting speed of the machine. Higher power and speed are essential for cutting harder woods and increasing productivity.

3. Software Compatibility

Ensure that the machine is compatible with the CAD/CAM software you plan to use. User-friendly software can simplify the design and programming process.

4. Budget

Determine your budget and choose a machine that offers the best value for your investment. Consider both the initial cost and ongoing maintenance expenses.

5. Support and Warranty

Look for a machine that comes with good customer support and a warranty. This ensures that you can get assistance if you encounter any issues.

Conclusion

CNC machines for wood are powerful tools that have transformed the woodworking industry. They offer unparalleled precision, efficiency, and versatility, making them indispensable for a wide range of applications. Whether you are a professional woodworker, a manufacturer, or a hobbyist, a CNC machine can help you achieve your creative and production goals. By understanding how these machines work, their components, types, and applications, you can make an informed decision when choosing the right CNC machine for your needs.