Introduction to CNC Machines and Their Costs

CNC (Computer Numerical Control) machines are a cornerstone of modern manufacturing, enabling precise and automated machining processes. These machines are used to cut, shape, and finish materials like metal, plastic, wood, and composites with unparalleled accuracy. While their capabilities are impressive, the cost of CNC machines can vary significantly depending on factors such as size, complexity, brand, and intended application. In this article, we will explore the various types of CNC machines, their price ranges, factors influencing costs, and additional expenses associated with owning and operating these machines.

Types of CNC Machines and Their Price Ranges

CNC machines come in various types, each designed for specific machining tasks. The cost of these machines varies widely based on their capabilities, size, and intended use. Below, we’ll break down the most common types of CNC machines and their associated price ranges.

1. CNC Milling Machines

CNC milling machines are among the most versatile and widely used CNC machines. They use rotary cutters to remove material from a workpiece, creating complex shapes and designs. CNC milling machines are categorized into three-axis, four-axis, and five-axis machines, with the number of axes indicating the level of complexity and precision they can achieve.

- Entry-Level CNC Mills: These machines are suitable for hobbyists and small workshops. Prices typically range from $5,000 to $20,000.

- Mid-Range CNC Mills: Designed for small to medium-sized businesses, these machines cost between $20,000 and $100,000.

- High-End CNC Mills: Industrial-grade machines with advanced features can cost anywhere from $100,000 to $500,000 or more.

2. CNC Lathes

CNC lathes are used for machining cylindrical parts by rotating the workpiece against a cutting tool. They are ideal for producing parts like shafts, bushings, and pulleys.

- Entry-Level CNC Lathes: These machines are suitable for basic turning operations and cost between $5,000 and $15,000.

- Mid-Range CNC Lathes: With enhanced features and capabilities, these machines are priced between $15,000 and $80,000.

- High-End CNC Lathes: Industrial-grade lathes with multi-axis capabilities can cost $80,000 to $300,000 or more.

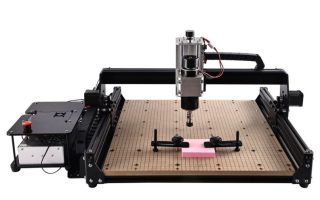

3. CNC Routers

CNC routers are commonly used for cutting and shaping wood, plastic, and soft metals. They are popular in industries like furniture making, sign manufacturing, and prototyping.

- Entry-Level CNC Routers: Suitable for hobbyists and small businesses, these machines cost between $2,000 and $10,000.

- Mid-Range CNC Routers: Designed for professional use, these machines are priced between $10,000 and $50,000.

- High-End CNC Routers: Industrial-grade routers with large work areas and advanced features can cost $50,000 to $150,000 or more.

4. CNC Plasma Cutters

CNC plasma cutters use a high-temperature plasma arc to cut through conductive materials like steel, aluminum, and copper. They are commonly used in metal fabrication and automotive industries.

- Entry-Level CNC Plasma Cutters: Basic models for hobbyists and small shops cost between $2,000 and $10,000.

- Mid-Range CNC Plasma Cutters: These machines, suitable for professional use, are priced between $10,000 and $50,000.

- High-End CNC Plasma Cutters: Industrial-grade machines with advanced features can cost $50,000 to $200,000 or more.

5. CNC Laser Cutters

CNC laser cutters use a focused laser beam to cut or engrave materials like metal, wood, acrylic, and fabric. They are widely used in industries like signage, jewelry, and electronics.

- Entry-Level CNC Laser Cutters: Basic models for hobbyists and small businesses cost between $2,000 and $10,000.

- Mid-Range CNC Laser Cutters: Designed for professional use, these machines are priced between $10,000 and $50,000.

- High-End CNC Laser Cutters: Industrial-grade machines with high power and precision can cost $50,000 to $300,000 or more.

6. CNC EDM Machines

CNC EDM (Electrical Discharge Machining) machines are used for machining hard materials and creating intricate shapes. They are commonly used in tool and die making.

- Entry-Level CNC EDM Machines: Basic models cost between $15,000 and $50,000.

- Mid-Range CNC EDM Machines: These machines are priced between $50,000 and $150,000.

- High-End CNC EDM Machines: Advanced models for industrial use can cost $150,000 to $500,000 or more.

Factors Influencing the Cost of CNC Machines

Several factors influence the cost of CNC machines, making it essential to understand these variables when budgeting for a purchase. Here are the key factors:

1. Machine Size and Work Area

The size of the CNC machine and its work area play a significant role in determining its cost. Larger machines with bigger work areas are generally more expensive due to the increased material and engineering required to build them.

2. Number of Axes

The number of axes a CNC machine has directly impacts its complexity and cost. Three-axis machines are the most basic and affordable, while five-axis machines, which offer greater flexibility and precision, are significantly more expensive.

3. Brand and Manufacturer

The brand and reputation of the manufacturer can also affect the price. Established brands with a history of reliability and performance often charge a premium for their machines.

4. Features and Capabilities

Advanced features like automatic tool changers, high-speed spindles, and integrated software can increase the cost of a CNC machine. Machines with higher precision and faster processing speeds are also more expensive.

5. Material and Build Quality

The materials used in constructing the machine and its overall build quality influence its durability and performance, which in turn affects the price.

6. New vs. Used Machines

Buying a used CNC machine can significantly reduce costs, but it may come with risks such as reduced reliability and higher maintenance expenses. New machines, while more expensive, often come with warranties and the latest technology.

Additional Costs Associated with CNC Machines

In addition to the initial purchase price, there are several other costs to consider when owning and operating a CNC machine:

1. Tooling and Accessories

CNC machines require various tools and accessories, such as cutting tools, clamps, and fixtures. These can add thousands of dollars to the overall cost.

2. Software

CNC machines rely on CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software for programming. Licensing fees for these software packages can range from a few hundred to several thousand dollars annually.

3. Maintenance and Repairs

Regular maintenance is essential to keep CNC machines running smoothly. Maintenance costs can include lubrication, part replacements, and servicing, which can add up over time.

4. Training and Labor

Operating a CNC machine requires skilled labor. Training employees to use the machine and hiring experienced operators can add to the overall cost.

5. Facility Requirements

CNC machines often require specific facility conditions, such as proper electrical supply, ventilation, and space. Upgrading your facility to accommodate the machine can be an additional expense.

Conclusion

CNC machines are a significant investment, with prices ranging from a few thousand dollars for entry-level models to several hundred thousand dollars for high-end industrial machines. The cost depends on factors such as the type of machine, its size, features, and brand. Additionally, potential buyers should consider the ongoing costs of tooling, software, maintenance, and labor. By understanding these factors, businesses and individuals can make informed decisions when purchasing a CNC machine, ensuring they select a model that meets their needs and budget.