Introduction to CNC Machines

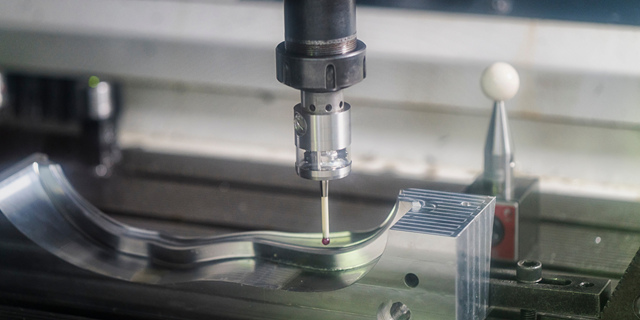

CNC (Computer Numerical Control) machines are automated tools controlled by a computer program to perform a wide variety of manufacturing tasks, such as cutting, drilling, milling, and turning. These machines are widely used in industries like aerospace, automotive, medical, and consumer goods manufacturing due to their precision, efficiency, and ability to produce complex parts. Learning to operate a CNC machine involves understanding both the hardware and software components, as well as the principles of machining and programming.

The time it takes to learn a CNC machine depends on several factors, including your prior experience, the complexity of the machine, the type of CNC machine (e.g., CNC lathe, CNC mill, or CNC router), and the depth of knowledge you wish to acquire. In this article, we will explore the learning process, the skills required, and the typical timeframes for becoming proficient in CNC machining.

Factors Influencing the Learning Timeline

1. **Prior Experience and Background**

If you have prior experience in machining, manufacturing, or working with similar equipment, you may find it easier to learn CNC machines. For example, a traditional machinist who already understands machining principles, tools, and materials may only need to learn the programming and software aspects of CNC. Conversely, someone with no prior experience in manufacturing may require more time to grasp the basics of machining before diving into CNC-specific skills.

2. **Type of CNC Machine**

Different types of CNC machines have varying levels of complexity. For instance, a CNC router used for woodworking may be simpler to learn than a 5-axis CNC milling machine used for aerospace components. The more complex the machine, the longer it may take to become proficient in its operation and programming.

3. **Depth of Knowledge Desired**

The time required to learn a CNC machine also depends on your goals. If you only need to operate the machine and run pre-programmed jobs, you can learn the basics relatively quickly. However, if you want to become proficient in CNC programming, toolpath optimization, and advanced machining techniques, you will need to invest more time and effort.

4. **Learning Resources and Methods**

The quality and availability of learning resources can significantly impact the time it takes to learn a CNC machine. Formal training programs, online courses, hands-on workshops, and mentorship from experienced machinists can accelerate the learning process. Self-taught learners may take longer, especially if they lack access to a CNC machine for practice.

Key Skills Required for CNC Machining

To become proficient in CNC machining, you need to develop a combination of technical, analytical, and practical skills. Below are the key skills required:

1. **Understanding of Machining Principles**

Machining principles include knowledge of cutting tools, materials, feeds and speeds, and machining processes such as turning, milling, and drilling. Understanding these principles is essential for selecting the right tools and parameters for a given job.

2. **CNC Programming**

CNC machines are controlled by G-code, a programming language that specifies the machine’s movements and operations. Learning to write, edit, and troubleshoot G-code is a critical skill for CNC machinists. Some modern CNC machines also use CAM (Computer-Aided Manufacturing) software to generate G-code automatically, so familiarity with CAM software is beneficial.

3. **Blueprint Reading and CAD Skills**

CNC machinists must be able to read and interpret engineering drawings and blueprints. Knowledge of CAD (Computer-Aided Design) software is also helpful for creating or modifying part designs before machining.

4. **Machine Setup and Operation**

Setting up a CNC machine involves tasks such as installing and calibrating tools, securing the workpiece, and loading the program. Operating the machine requires monitoring its performance, making adjustments as needed, and ensuring quality control.

5. **Problem-Solving and Troubleshooting**

CNC machinists often encounter issues such as tool wear, machine errors, or programming mistakes. The ability to diagnose and resolve these problems is essential for maintaining productivity and quality.

Typical Learning Timeline

The time it takes to learn a CNC machine can vary widely depending on the factors mentioned earlier. Below is a general timeline for different levels of proficiency:

1. **Basic Operation: 1 to 3 Months**

Learning the basics of CNC machine operation, such as loading programs, setting up tools, and running simple jobs, can take as little as one to three months. This level of knowledge is sufficient for entry-level positions where the machinist primarily operates the machine rather than programming it.

2. **Intermediate Skills: 6 to 12 Months**

Developing intermediate skills, such as writing and editing G-code, setting up complex jobs, and troubleshooting common issues, typically takes six to twelve months. This level of proficiency allows you to handle a wider range of tasks and work more independently.

3. **Advanced Proficiency: 1 to 3 Years**

Achieving advanced proficiency in CNC machining, including expertise in CAM software, multi-axis machining, and process optimization, can take one to three years of dedicated practice and learning. At this level, you can take on complex projects, mentor others, and contribute to process improvements.

Learning Resources and Strategies

To accelerate your learning process, consider the following resources and strategies:

1. **Formal Training Programs**

Many community colleges, technical schools, and trade organizations offer CNC machining courses and certifications. These programs provide structured learning and hands-on experience with CNC machines.

2. **Online Courses and Tutorials**

Online platforms like Udemy, Coursera, and LinkedIn Learning offer courses on CNC programming, G-code, and CAM software. These resources are convenient for self-paced learning.

3. **On-the-Job Training**

Many employers provide on-the-job training for CNC machinists. Working under the guidance of experienced professionals allows you to learn practical skills and gain real-world experience.

4. **Practice and Experimentation**

Hands-on practice is essential for mastering CNC machining. If you have access to a CNC machine, spend time experimenting with different tools, materials, and programs to build your skills.

5. **Books and Manuals**

Books and manuals on CNC machining, G-code programming, and machining principles can provide valuable theoretical knowledge. Some popular titles include “CNC Programming Handbook” by Peter Smid and “Machinery’s Handbook.”

Conclusion

Learning to operate and program a CNC machine is a rewarding journey that opens up numerous career opportunities in manufacturing and engineering. The time it takes to learn depends on your background, the type of machine, and the depth of knowledge you wish to acquire. With dedication, practice, and the right resources, you can become proficient in CNC machining and contribute to the production of high-quality, precision-engineered components.

Whether you are a beginner looking to enter the field or an experienced machinist aiming to upgrade your skills, the key to success is consistent learning and hands-on experience. Start with the basics, build your knowledge step by step, and don’t hesitate to seek guidance from experts in the field.