Introduction to Home CNC Machines

CNC (Computer Numerical Control) machines have revolutionized the manufacturing and fabrication industries by automating the process of cutting, milling, engraving, and other operations. In recent years, the availability of smaller, more affordable CNC machines has made it possible for hobbyists, small business owners, and DIY enthusiasts to bring this technology into their homes or workshops. These home CNC machines are ideal for woodworking, metalworking, engraving, and even 3D printing, offering precision and repeatability that manual tools cannot match.

One of the most common questions for those considering a home CNC machine is, “How much do they cost?” The answer depends on several factors, including the type of CNC machine, its size, features, and intended use. In this article, we will explore the various types of home CNC machines, their price ranges, and the factors that influence their cost. By the end, you’ll have a comprehensive understanding of what to expect when budgeting for a home CNC machine.

Types of Home CNC Machines

Before diving into the costs, it’s essential to understand the different types of CNC machines available for home use. Each type serves a specific purpose and comes with its own set of features and price points. Below are the most common types:

1. CNC Routers

CNC routers are among the most popular types of CNC machines for home use. They are primarily used for cutting and engraving wood, plastic, and soft metals like aluminum. CNC routers are versatile and can handle tasks like carving intricate designs, creating furniture, and even making signs. They are available in various sizes, from compact desktop models to larger machines suitable for small workshops.

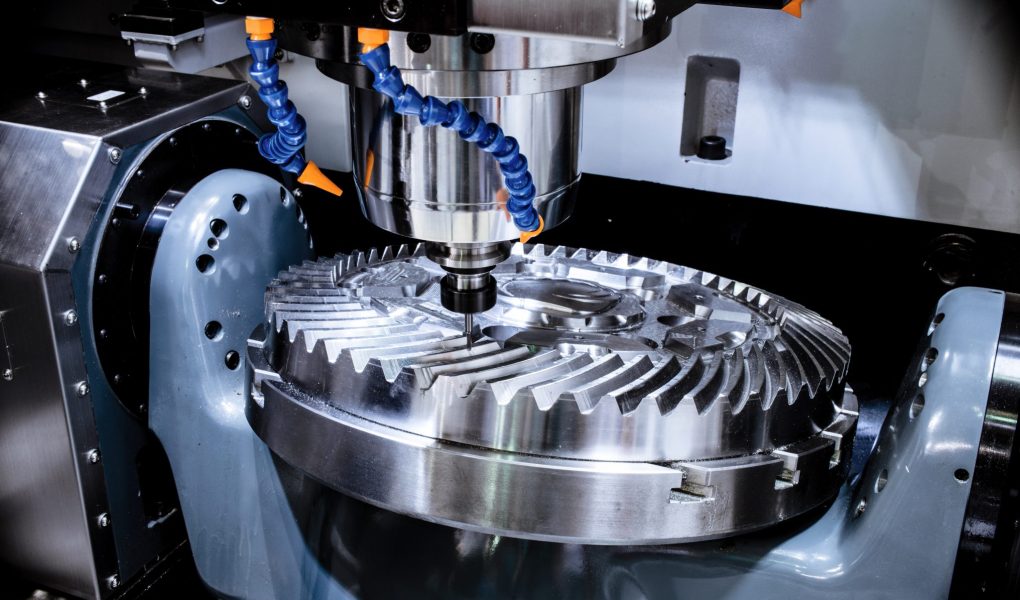

2. CNC Mills

CNC mills are designed for more precise and heavy-duty operations compared to CNC routers. They are capable of cutting harder materials like steel and titanium, making them ideal for machining metal parts. While they are more expensive than CNC routers, they offer higher precision and durability. CNC mills are commonly used by hobbyists and small-scale manufacturers who need to produce metal components.

3. CNC Lathes

CNC lathes are specialized machines used for turning operations, where the workpiece rotates while a cutting tool shapes it. These machines are ideal for creating cylindrical objects like spindles, bowls, and mechanical parts. CNC lathes are less common in home settings due to their specialized nature and higher cost, but they are invaluable for specific applications.

4. CNC Plasma Cutters

CNC plasma cutters use a high-temperature plasma torch to cut through electrically conductive materials like steel, aluminum, and brass. These machines are popular among metalworkers and fabricators for their ability to make precise cuts quickly. While they are generally more expensive than CNC routers, they are an excellent choice for those who work primarily with metal.

5. CNC Laser Cutters and Engravers

CNC laser cutters and engravers use a focused laser beam to cut or engrave materials like wood, acrylic, leather, and even metal. They are highly precise and can produce intricate designs, making them popular for artistic and decorative applications. Laser cutters are available in a wide price range, depending on their power and capabilities.

6. CNC 3D Printers

While not traditionally considered CNC machines, 3D printers operate on similar principles, using computer-controlled movements to create objects layer by layer. They are widely used for prototyping, model-making, and even small-scale manufacturing. 3D printers are among the most affordable CNC machines, making them accessible to a broad audience.

Price Ranges for Home CNC Machines

The cost of a home CNC machine can vary widely based on its type, size, and features. Below is a breakdown of the typical price ranges for each type of CNC machine:

1. CNC Routers

– **Entry-Level Models:** $300 to $1,000

– **Mid-Range Models:** $1,000 to $3,000

– **High-End Models:** $3,000 to $10,000+

Entry-level CNC routers are compact and suitable for hobbyists working on small projects. Mid-range models offer larger work areas and better build quality, while high-end models are designed for professional use and can handle more demanding tasks.

2. CNC Mills

– **Entry-Level Models:** $2,000 to $5,000

– **Mid-Range Models:** $5,000 to $15,000

– **High-End Models:** $15,000 to $50,000+

CNC mills are generally more expensive than routers due to their higher precision and ability to machine harder materials. Entry-level models are suitable for light-duty tasks, while high-end models are used in professional and industrial settings.

3. CNC Lathes

– **Entry-Level Models:** $3,000 to $8,000

– **Mid-Range Models:** $8,000 to $20,000

– **High-End Models:** $20,000 to $50,000+

CNC lathes are specialized machines with a higher price point. They are typically used by professionals who need to produce cylindrical parts with high precision.

4. CNC Plasma Cutters

– **Entry-Level Models:** $1,500 to $5,000

– **Mid-Range Models:** $5,000 to $15,000

– **High-End Models:** $15,000 to $30,000+

Plasma cutters are priced based on their cutting capacity and features. Entry-level models are suitable for hobbyists, while high-end models are designed for industrial use.

5. CNC Laser Cutters and Engravers

– **Entry-Level Models:** $300 to $1,500

– **Mid-Range Models:** $1,500 to $10,000

– **High-End Models:** $10,000 to $50,000+

Laser cutters and engravers vary widely in price depending on their power and capabilities. Entry-level models are suitable for small projects, while high-end models can handle larger and more complex tasks.

6. CNC 3D Printers

– **Entry-Level Models:** $200 to $500

– **Mid-Range Models:** $500 to $2,000

– **High-End Models:** $2,000 to $10,000+

3D printers are among the most affordable CNC machines, with entry-level models accessible to most hobbyists. High-end models offer advanced features like multi-material printing and larger build volumes.

Factors Influencing the Cost of Home CNC Machines

Several factors influence the cost of a home CNC machine. Understanding these factors can help you make an informed decision and choose a machine that meets your needs and budget.

1. Size and Work Area

The size of the CNC machine and its work area significantly impact its cost. Larger machines with more extensive work areas are generally more expensive but offer greater versatility for handling larger projects.

2. Material Compatibility

Machines capable of cutting or engraving harder materials like steel or titanium are more expensive than those designed for softer materials like wood or plastic. Consider the materials you plan to work with when choosing a machine.

3. Precision and Accuracy

Higher precision and accuracy come at a cost. Machines with tighter tolerances and better repeatability are more expensive but are essential for projects requiring high levels of detail.

4. Build Quality and Durability

The build quality of the machine affects its durability and performance. Machines made from high-quality materials like steel and aluminum are more expensive but offer better longevity and stability.

5. Software and Features

CNC machines come with various software options and features, such as touchscreen controls, automatic tool changers, and advanced programming capabilities. These features can add to the cost but improve usability and efficiency.

6. Brand and Support

Well-known brands with a reputation for quality and customer support often charge a premium for their machines. While these machines may be more expensive, they often come with better warranties and technical support.

Conclusion

The cost of home CNC machines varies widely, ranging from a few hundred dollars for entry-level models to tens of thousands of dollars for high-end machines. When choosing a CNC machine, consider your specific needs, budget, and the types of projects you plan to undertake. By understanding the different types of CNC machines and the factors that influence their cost, you can make an informed decision and invest in a machine that will serve you well for years to come.

Whether you’re a hobbyist looking to explore CNC technology or a small business owner seeking to expand your capabilities, there’s a CNC machine out there to fit your needs and budget. Take the time to research and compare options, and you’ll be well on your way to unlocking the potential of CNC machining in your home or workshop.