Introduction to Home CNC Machines

CNC (Computer Numerical Control) machines have revolutionized the manufacturing and crafting industries by automating complex machining processes. These machines are capable of cutting, milling, engraving, and shaping materials with precision and repeatability. While CNC machines were once limited to industrial settings due to their high cost and complexity, advancements in technology have made them more accessible to hobbyists, small businesses, and home users. Home CNC machines, often smaller and more affordable than their industrial counterparts, allow users to create intricate designs and prototypes from the comfort of their homes.

One of the most common questions for those considering a home CNC machine is: “How much do they cost?” The answer depends on several factors, including the type of machine, its capabilities, and the intended use. In this article, we will explore the various types of home CNC machines, their price ranges, and the factors that influence their cost. Additionally, we will provide insights into the hidden costs associated with owning and operating a CNC machine.

Types of Home CNC Machines

Before diving into the costs, it’s important to understand the different types of CNC machines available for home use. Each type serves a specific purpose and comes with its own set of features and price points. Below are the most common types of home CNC machines:

1. CNC Routers

CNC routers are among the most popular types of CNC machines for home use. They are designed to cut and carve materials such as wood, plastic, foam, and soft metals. CNC routers are versatile and are often used for woodworking, sign-making, and crafting. They come in various sizes, from desktop models to larger units that can handle bigger projects.

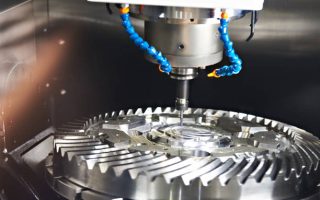

2. CNC Mills

CNC mills are more robust than CNC routers and are designed to cut harder materials like metals. They are commonly used for machining parts, prototypes, and molds. Home CNC mills are typically smaller and less powerful than industrial models but are still capable of producing high-quality results.

3. CNC Laser Cutters and Engravers

CNC laser machines use a high-powered laser to cut or engrave materials. They are ideal for precision work on materials like wood, acrylic, leather, and certain metals. Laser cutters are popular among hobbyists and small businesses for creating intricate designs, custom products, and artwork.

4. CNC Plasma Cutters

CNC plasma cutters are designed to cut through conductive materials such as steel, aluminum, and copper using a plasma torch. These machines are commonly used for metalworking projects and are less common in home settings due to their size and cost.

5. CNC Lathes

CNC lathes are used for turning operations, where the material is rotated while a cutting tool shapes it. They are ideal for creating cylindrical objects like spindles, bowls, and mechanical parts. Home CNC lathes are smaller and more affordable than industrial models but still offer a high level of precision.

6. 3D Printers (FDM and SLA)

While not traditional CNC machines, 3D printers are often included in discussions about home CNC equipment. They use additive manufacturing techniques to create objects layer by layer. FDM (Fused Deposition Modeling) and SLA (Stereolithography) are the most common types of 3D printers for home use.

Price Ranges for Home CNC Machines

The cost of a home CNC machine can vary widely depending on its type, size, and capabilities. Below is a breakdown of the typical price ranges for each type of machine:

1. CNC Routers

– **Entry-Level Models:** $300 – $1,000

Entry-level CNC routers are compact and designed for hobbyists. They are suitable for small projects and light-duty work.

– **Mid-Range Models:** $1,000 – $3,000

Mid-range CNC routers offer larger work areas, better build quality, and more powerful motors. They are ideal for serious hobbyists and small businesses.

– **High-End Models:** $3,000 – $10,000+

High-end CNC routers are designed for professional use and can handle larger projects and heavier materials. They often come with advanced features like automatic tool changers and high-speed spindles.

2. CNC Mills

– **Entry-Level Models:** $1,000 – $3,000

Entry-level CNC mills are compact and suitable for light-duty machining. They are often used for small metalworking projects.

– **Mid-Range Models:** $3,000 – $10,000

Mid-range CNC mills offer better precision, larger work areas, and more powerful motors. They are suitable for more demanding projects.

– **High-End Models:** $10,000 – $50,000+

High-end CNC mills are designed for professional and industrial use. They offer advanced features and can handle heavy-duty machining tasks.

3. CNC Laser Cutters and Engravers

– **Entry-Level Models:** $200 – $1,000

Entry-level laser engravers are compact and suitable for light-duty engraving on materials like wood and acrylic.

– **Mid-Range Models:** $1,000 – $5,000

Mid-range laser cutters offer more power and larger work areas. They can handle more demanding projects and a wider range of materials.

– **High-End Models:** $5,000 – $20,000+

High-end laser cutters are designed for professional use and can handle heavy-duty cutting and engraving tasks. They often come with advanced features like higher wattage lasers and air assist systems.

4. CNC Plasma Cutters

– **Entry-Level Models:** $1,000 – $3,000

Entry-level plasma cutters are compact and suitable for light-duty metal cutting.

– **Mid-Range Models:** $3,000 – $10,000

Mid-range plasma cutters offer larger work areas and more powerful torches. They are suitable for more demanding projects.

– **High-End Models:** $10,000 – $30,000+

High-end plasma cutters are designed for professional use and can handle heavy-duty metal cutting tasks.

5. CNC Lathes

– **Entry-Level Models:** $1,000 – $3,000

Entry-level CNC lathes are compact and suitable for light-duty turning operations.

– **Mid-Range Models:** $3,000 – $10,000

Mid-range CNC lathes offer better precision and larger work areas. They are suitable for more demanding projects.

– **High-End Models:** $10,000 – $50,000+

High-end CNC lathes are designed for professional and industrial use. They offer advanced features and can handle heavy-duty turning tasks.

6. 3D Printers

– **Entry-Level Models:** $200 – $500

Entry-level 3D printers are compact and suitable for hobbyists. They are ideal for small projects and prototyping.

– **Mid-Range Models:** $500 – $2,000

Mid-range 3D printers offer better build quality, larger print areas, and more advanced features.

– **High-End Models:** $2,000 – $10,000+

High-end 3D printers are designed for professional use and can handle more complex projects and materials.

Factors Influencing the Cost of Home CNC Machines

Several factors influence the cost of a home CNC machine. Understanding these factors can help you make an informed decision when choosing a machine:

1. Build Quality

The build quality of a CNC machine affects its durability, precision, and performance. Machines made from high-quality materials like aluminum or steel are more expensive but offer better performance and longevity.

2. Size and Work Area

Larger CNC machines with bigger work areas are generally more expensive. The size of the machine you need depends on the type of projects you plan to undertake.

3. Motor and Spindle Power

The power of the motor and spindle determines the machine’s ability to cut through different materials. More powerful motors and spindles are more expensive but can handle tougher materials and faster cutting speeds.

4. Features and Accessories

Advanced features like automatic tool changers, dust collection systems, and touchscreen interfaces can increase the cost of a CNC machine. Additionally, accessories like clamps, bits, and software add to the overall expense.

5. Brand and Reputation

Well-known brands with a reputation for quality and reliability often charge a premium for their machines. While these machines may be more expensive, they often come with better customer support and warranties.

Hidden Costs of Owning a Home CNC Machine

In addition to the upfront cost of the machine, there are several hidden costs associated with owning and operating a CNC machine. These include:

1. Software

Most CNC machines require CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to create and process designs. While some machines come with free software, others require you to purchase it separately, which can cost anywhere from $100 to $1,000 or more.

2. Tools and Consumables

Cutting tools, bits, and other consumables need to be replaced periodically. The cost of these items can add up over time, especially if you work on a variety of materials.

3. Maintenance

Regular maintenance is essential to keep your CNC machine running smoothly. This includes cleaning, lubrication, and replacing worn parts. Maintenance costs can vary depending on the machine and its usage.

4. Training and Learning Curve

Learning to operate a CNC machine and its software can take time and effort. Some users may choose to invest in training courses or tutorials, which can add to the overall cost.

5. Workspace Setup

Setting up a dedicated workspace for your CNC machine may require additional expenses, such as a sturdy workbench, ventilation systems, and safety equipment.

Conclusion

The cost of a home CNC machine can range from a few hundred dollars to tens of thousands of dollars, depending on the type, size, and features of the machine. While entry-level models are affordable and suitable for hobbyists, mid-range and high-end models offer better performance and are ideal for more demanding projects. When budgeting for a CNC machine, it’s important to consider not only the upfront cost but also the hidden costs associated with software, tools, maintenance, and workspace setup.

Ultimately, the right CNC machine for you will depend on your specific needs, skills, and budget. By understanding the various options and costs, you can make an informed decision and enjoy the benefits of owning a home CNC machine.