Introduction to CNC Machines

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry by enabling precision, efficiency, and automation in machining processes. These machines use pre-programmed computer software to control the movement of tools and machinery, allowing for the production of complex parts with minimal human intervention. CNC machines are widely used across industries such as aerospace, automotive, electronics, and medical device manufacturing. There are various types of CNC machines, each designed for specific applications and machining tasks. In this article, we will explore the five most common types of CNC machines, their functions, and their applications.

1. CNC Milling Machines

Overview of CNC Milling Machines

CNC milling machines are among the most versatile and widely used CNC machines in the manufacturing industry. These machines use rotary cutting tools to remove material from a workpiece, creating precise shapes and features. The cutting tools are mounted on a spindle, which rotates at high speeds to perform the machining operations. CNC milling machines can handle a wide range of materials, including metals, plastics, and composites.

Key Features of CNC Milling Machines

– **Multi-Axis Capability:** CNC milling machines typically operate on three to five axes, allowing for complex and precise machining. Three-axis machines move along the X, Y, and Z axes, while five-axis machines add rotational movements for greater flexibility.

– **High Precision:** These machines are capable of achieving tight tolerances, making them ideal for applications that require high accuracy.

– **Tool Changers:** Many CNC milling machines are equipped with automatic tool changers, which allow for the use of multiple tools in a single machining process.

Applications of CNC Milling Machines

CNC milling machines are used in a variety of industries for tasks such as prototyping, custom part production, and mass manufacturing. Common applications include:

– Manufacturing molds and dies

– Producing automotive components

– Creating medical devices and implants

– Fabricating aerospace parts

2. CNC Lathes

Overview of CNC Lathes

CNC lathes are specialized machines designed for turning operations. They rotate the workpiece while a stationary cutting tool removes material to create cylindrical shapes. CNC lathes are highly efficient and capable of producing parts with excellent surface finishes and tight tolerances. These machines are commonly used for machining shafts, bushings, and other round components.

Key Features of CNC Lathes

– **High-Speed Spindles:** CNC lathes are equipped with high-speed spindles that enable rapid material removal and efficient machining.

– **Live Tooling:** Some CNC lathes feature live tooling capabilities, allowing for additional operations such as drilling, milling, and tapping without removing the workpiece from the machine.

– **Bar Feeders:** Many CNC lathes are equipped with bar feeders, which automatically supply raw material to the machine for continuous production.

Applications of CNC Lathes

CNC lathes are widely used in industries such as automotive, aerospace, and oil and gas. Common applications include:

– Producing shafts, rods, and pins

– Machining threaded components

– Creating custom fittings and connectors

– Fabricating hydraulic and pneumatic components

3. CNC Plasma Cutters

Overview of CNC Plasma Cutters

CNC plasma cutters are machines that use a high-temperature plasma arc to cut through electrically conductive materials such as steel, aluminum, and copper. These machines are known for their speed, precision, and ability to cut intricate shapes. CNC plasma cutters are commonly used in metal fabrication and construction industries.

Key Features of CNC Plasma Cutters

– **High Cutting Speeds:** CNC plasma cutters can cut through materials quickly, making them ideal for high-volume production.

– **Precision Cutting:** These machines are capable of producing clean and precise cuts with minimal material waste.

– **Versatility:** CNC plasma cutters can handle a wide range of material thicknesses and are suitable for cutting both flat and curved surfaces.

Applications of CNC Plasma Cutters

CNC plasma cutters are used in various industries for tasks such as:

– Cutting metal sheets and plates

– Fabricating metal signs and artwork

– Producing structural components for buildings and bridges

– Manufacturing automotive and industrial parts

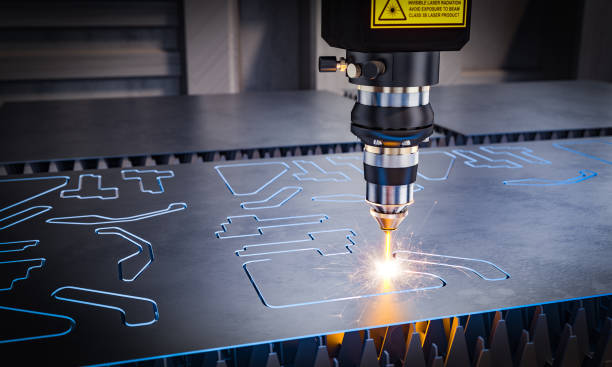

4. CNC Laser Cutters

Overview of CNC Laser Cutters

CNC laser cutters use a focused laser beam to cut or engrave materials with high precision. These machines are capable of producing intricate designs and are commonly used for cutting thin materials such as sheet metal, plastic, and wood. CNC laser cutters are widely used in industries such as electronics, jewelry, and signage.

Key Features of CNC Laser Cutters

– **High Precision:** CNC laser cutters can achieve extremely fine cuts and detailed engravings, making them ideal for intricate designs.

– **Non-Contact Cutting:** The laser beam does not physically touch the material, reducing the risk of damage or deformation.

– **Versatility:** These machines can cut and engrave a wide range of materials, including metals, plastics, wood, and glass.

Applications of CNC Laser Cutters

CNC laser cutters are used for a variety of applications, including:

– Creating custom signage and displays

– Engraving logos and designs on products

– Cutting intricate patterns for jewelry and ornaments

– Fabricating electronic components and enclosures

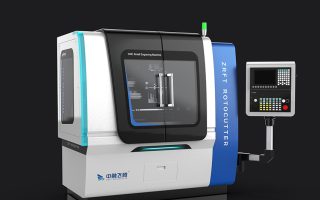

5. CNC Electrical Discharge Machines (EDM)

Overview of CNC EDM Machines

CNC electrical discharge machines (EDM) use electrical discharges (sparks) to remove material from a workpiece. These machines are highly specialized and are typically used for machining hard materials and creating complex shapes that are difficult to achieve with traditional cutting tools. There are two main types of CNC EDM machines: wire EDM and sinker EDM.

Key Features of CNC EDM Machines

– **Precision Machining:** CNC EDM machines are capable of achieving extremely tight tolerances and smooth surface finishes.

– **Complex Geometry:** These machines can create intricate shapes and features, such as internal corners and cavities.

– **Material Versatility:** CNC EDM machines can machine hard materials such as tool steel, titanium, and carbide.

Applications of CNC EDM Machines

CNC EDM machines are commonly used in industries such as aerospace, automotive, and tool and die manufacturing. Typical applications include:

– Creating molds and dies

– Machining intricate components for aerospace and medical devices

– Producing custom tooling and fixtures

– Fabricating parts with tight tolerances and complex geometries

Conclusion

CNC machines have transformed the manufacturing landscape by enabling precise, efficient, and automated machining processes. The five common types of CNC machines—milling machines, lathes, plasma cutters, laser cutters, and EDM machines—each serve unique purposes and are suited for specific applications. Understanding the capabilities and applications of these machines is essential for selecting the right equipment for your manufacturing needs. As technology continues to advance, CNC machines will play an increasingly vital role in driving innovation and productivity across industries.