Introduction to CNC Machine Operation

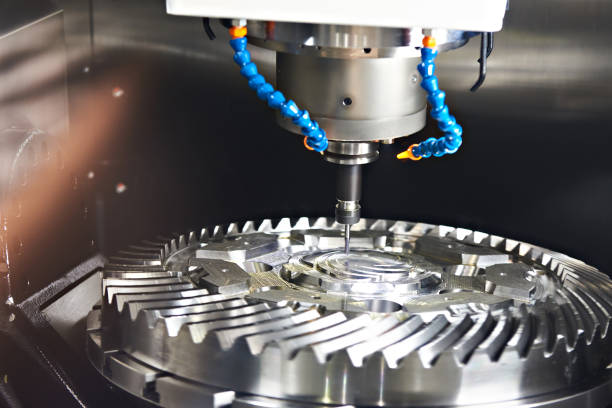

CNC (Computer Numerical Control) machines are an integral part of modern manufacturing processes. These machines are used to automate the control of machining tools, such as drills, lathes, and mills, through computer programming. CNC machine operators play a crucial role in ensuring the smooth operation of these machines, enabling manufacturers to produce high-quality parts and components with precision and efficiency. This article will provide an in-depth exploration of what a CNC machine operator does, their responsibilities, required skills, and the significance of their role in the manufacturing industry.

Who is a CNC Machine Operator?

A CNC machine operator is a skilled professional responsible for setting up, operating, and maintaining CNC machines. They work in various industries, including automotive, aerospace, electronics, and medical device manufacturing. Their primary goal is to ensure that CNC machines produce parts that meet the required specifications, quality standards, and production schedules.

While CNC machines are highly automated, they still require human oversight to ensure optimal performance. CNC machine operators bridge the gap between advanced technology and human expertise, making them indispensable in modern manufacturing environments.

Key Responsibilities of a CNC Machine Operator

The role of a CNC machine operator encompasses a wide range of responsibilities, from machine setup to quality control. Below are the primary duties associated with this role:

1. Machine Setup

Before production begins, CNC machine operators are responsible for setting up the machine. This involves:

- Loading the required tools and fixtures into the machine.

- Installing the raw material (e.g., metal, plastic, or wood) onto the machine bed or chuck.

- Configuring the machine’s settings, such as speed, feed rate, and cutting depth, based on the job specifications.

- Inputting the CNC program, which contains the instructions for the machine to follow during the machining process.

2. Operating the CNC Machine

Once the machine is set up, the operator starts the production process. During operation, they monitor the machine’s performance to ensure it is functioning correctly. This includes:

- Observing the machining process to identify any irregularities or errors.

- Making real-time adjustments to machine settings if necessary.

- Ensuring that the machine runs efficiently and meets production targets.

3. Quality Control

Quality is a top priority in manufacturing, and CNC machine operators play a key role in maintaining it. Their quality control responsibilities include:

- Inspecting finished parts using precision measuring tools, such as calipers, micrometers, and coordinate measuring machines (CMMs).

- Comparing the parts to blueprints or CAD (Computer-Aided Design) models to ensure they meet the required specifications.

- Documenting inspection results and reporting any defects or deviations to supervisors or engineers.

4. Maintenance and Troubleshooting

CNC machines require regular maintenance to operate efficiently. CNC machine operators are responsible for performing routine maintenance tasks, such as:

- Cleaning the machine and its components to prevent debris buildup.

- Lubricating moving parts to reduce wear and tear.

- Replacing worn-out tools and fixtures as needed.

In addition to maintenance, operators must troubleshoot and resolve any issues that arise during operation. This may involve diagnosing mechanical or programming errors and implementing corrective actions to minimize downtime.

5. Documentation and Reporting

CNC machine operators are often required to maintain detailed records of their work. This includes:

- Logging machine settings and adjustments for future reference.

- Recording production data, such as the number of parts produced and the time taken for each job.

- Reporting any issues or anomalies to supervisors or engineers.

Skills and Qualifications Required for CNC Machine Operators

To excel as a CNC machine operator, individuals need a combination of technical skills, problem-solving abilities, and attention to detail. Below are the key skills and qualifications required for this role:

1. Technical Skills

CNC machine operators must have a strong understanding of machining principles and techniques. This includes knowledge of:

- Blueprint reading and interpretation.

- G-code and M-code programming languages used in CNC machines.

- Tool selection and cutting parameters.

- Precision measuring instruments and quality control methods.

2. Problem-Solving Abilities

CNC machine operators must be able to identify and resolve issues quickly to minimize production delays. This requires strong analytical and troubleshooting skills, as well as the ability to think critically under pressure.

3. Attention to Detail

Precision is paramount in CNC machining. Operators must pay close attention to details to ensure that parts meet exact specifications. Even minor errors can lead to costly defects or rework.

4. Communication Skills

Effective communication is essential for collaborating with team members, supervisors, and engineers. CNC machine operators must be able to convey information clearly and accurately, both verbally and in writing.

5. Physical Stamina

Operating CNC machines often involves standing for long periods, lifting heavy materials, and working in noisy environments. Physical stamina and the ability to adhere to safety protocols are important for this role.

Training and Certification

Becoming a CNC machine operator typically requires a combination of formal education, on-the-job training, and certification. Here are the common pathways to entering this profession:

1. Formal Education

Many CNC machine operators begin their careers by completing a vocational or technical program in machining, manufacturing technology, or a related field. These programs provide foundational knowledge in CNC programming, machine operation, and quality control.

2. On-the-Job Training

Entry-level operators often receive on-the-job training from experienced colleagues or supervisors. This hands-on experience is invaluable for learning the specific machines, tools, and processes used in a particular workplace.

3. Certification

Certifications, such as those offered by the National Institute for Metalworking Skills (NIMS) or the Manufacturing Skill Standards Council (MSSC), can enhance an operator’s credentials and job prospects. These certifications validate an individual’s skills and knowledge in CNC machining and related areas.

The Importance of CNC Machine Operators in Manufacturing

CNC machine operators are vital to the success of manufacturing operations. Their expertise ensures that CNC machines produce high-quality parts efficiently and reliably. By maintaining tight tolerances and adhering to production schedules, operators contribute to the overall productivity and profitability of their organizations.

In addition, CNC machine operators play a key role in driving innovation and competitiveness in the manufacturing industry. Their ability to adapt to new technologies and processes enables companies to stay ahead in a rapidly evolving market.

Conclusion

CNC machine operators are the backbone of modern manufacturing, combining technical expertise with hands-on skills to produce precision parts and components. Their responsibilities encompass machine setup, operation, quality control, maintenance, and troubleshooting, making them indispensable in ensuring the efficiency and quality of production processes. As manufacturing continues to evolve, the demand for skilled CNC machine operators is expected to grow, offering rewarding career opportunities for those who choose this path.